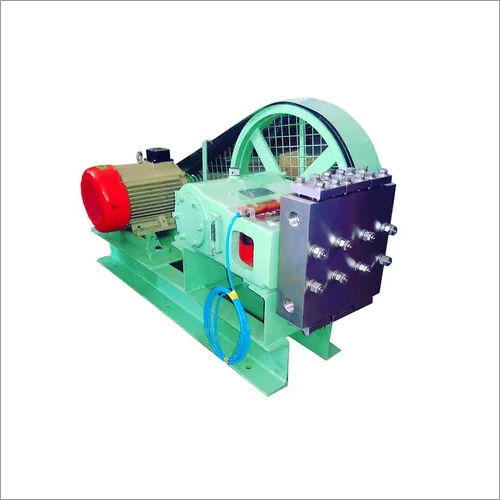

Hydro Test Pump

75000.00 - 300000.00 INR/Unit

Product Details:

- Speed 1440 RPM

- Features Heavy duty construction, corrosion resistant, easy maintenance

- Working Temperature -10C to +50C

- Discharge Pressure High Pressure

- Noise Level Less than 80 dB

- Flow Rate 10-500 LPH

- Head Size Up to 700 meters

- Click to View more

X

Hydro Test Pump Price And Quantity

- 75000.00 - 300000.00 INR/Unit

- 1 Unit

Hydro Test Pump Product Specifications

- 50 Hz

- Pipes, Valves, Pressure Vessels

- 0.75kW - 5kW

- Plunger / Piston Type

- IS: 6286

- Reciprocating Pump

- Electric

- Manual/Automatic

- 3.5 meters

- Floor/Skid Mounted

- Hydrostatic Pressure Testing

- Up to 700 kg/cm2

- Less than 80 dB

- High Pressure

- -10C to +50C

- Customized

- Up to 700 meters

- Positive Displacement

- 10-500 LPH

- Variable (as per requirement)

- Portable Skid Mounted

- Manual

- High Pressure PTFE Seals

- 220V / 380V

- 1/2 BSP

- Stainless Steel / Mild Steel

- Heavy duty construction, corrosion resistant, easy maintenance

- 1440 RPM

Hydro Test Pump Trade Information

- 1 Unit Per Day

- 3 Days

Product Description

Use our top most quality Hydro Test Pumps which are perfectly designed. They are engineered to test plumbing lines, solar systems, pressure vessels, water meters, sprinkler systems and many more. The offered products find their applications in commercial as well as residential areas. They are highly appreciated for their excellent performance. They require less maintenance and save cost and power. These machines are portable, give fast result, have compact design and many more. The Hydro Test Pumps are highly beneficial and efficient in nature.

Versatile Testing with Enhanced Safety

Engineered for hydrostatic pressure testing, this pump supports both water and oil as test mediums and incorporates inbuilt overpressure protection through a precision safety valve. The robust stainless steel or mild steel construction ensures durability, while a manual priming system facilitates reliable operation even in challenging environments.

Portability Meets Heavy Duty Performance

Despite its heavy-duty build and high-pressure capability (up to 700 kg/cm), the pump remains portable, featuring a carry handle and export-grade wooden box for safe transportation. The lightweight structure (approx. 30 kg) and manual or automatic controls enhance usability at various worksites.

Customizable Features for Diverse Applications

Catering to industrial requirements, the pump offers adjustable flow rates (10500 LPH), head sizes up to 700 meters, and can be supplied with optional extras such as a digital pressure recorder or additional hoses. Its compatibility with varying voltages (220V/380V) and strict compliance with IS: 6286 standards ensure reliable performance across industries.

FAQs of Hydro Test Pump:

Q: How do you operate the Hydro Test Pump for hydrostatic pressure testing?

A: Start by connecting the pump to your test object (such as pipes or pressure vessels) using the supplied 5-meter hose. Fill the reservoir with the chosen test medium (water or oil), ensure manual priming if required, and select manual or automatic controls as needed. Gradually increase pressure while monitoring the panel-mounted, glycerin-filled gauge until the desired test pressure is achieved.Q: What safety features are included to protect against overpressure?

A: The unit features an inbuilt safety valve that automatically relieves excess pressure, preventing equipment damage or safety hazards during testing. The robust, corrosion-resistant body, combined with IP55 insulation, ensures safe operation under various conditions.Q: When should you request optional accessories like the digital pressure recorder?

A: Optional accessories, such as a digital pressure recorder or extra hose, should be requested when precise digital logging of pressure data is required or when additional reach or connections are necessary for specific testing scenarios. These options cater to specialized needs or industry-specific standards.Q: Where can the Hydro Test Pump be used effectively?

A: This pump is suitable for industrial settings, construction sites, maintenance workshops, or anywhere pipes, valves, and pressure vessels require thorough hydrostatic testing. Its portability and versatile mounting options (floor or skid-mounted) allow deployment in varied environments.Q: What is the process of performing a hydrostatic test using this pump?

A: First, connect the pumps inlet/outlet (1/2" BSP) to the system under test. Fill the system with water or oil, prime the pump, and increase the pressure using manual or automatic controls. Observe the pressure gauge until the desired level is reached and maintain it to verify system integrity. Discharge and safely depressurize after completion.Q: What are the key benefits of this Hydro Test Pump compared to standard models?

A: The pump offers heavy-duty, corrosion-resistant construction, easy portability, adjustable capacity, and inbuilt safety mechanisms. Customized configurations, quiet operation (under 80 dB), and a variable pressure range up to 700 kg/cm make it ideal for diverse industrial testing requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Triplex High Pressure Pumps' category

"All type of liquid and Semi-liquid Homogenizers are available."

|

HARVEST HI-TECH EQUIPMENTS (INDIA) PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Call Me Free

Call Me Free